The Hemingray No 9 Revisited

by Charlie Angevine, NIA #348

Reprinted from "INSULATORS - Crown Jewels of the Wire", May 1980, page 9

It has been nearly five years since I

wrote the first story about my specialty collection (Crown Jewels, July 1975).

In addition to my collection growing in size since then, new information has

come to light. At the urging of friends and fellow collectors, I will try to

bring the story up to date.

Correspondence with Mr. N. R. Woodward has provided

me with the information needed to date the embossing arrangements I have found.

(See table 3.) Correspondence with Mr. Glenn Drummond has led to the conclusion

that all CD 106 HEMINGRAY NO 9's were made in Muncie. After arriving at this

conclusion with Glenn, doesn't he turn around and send me one of them that he

dug from the Covington dump.

In addition to feeling indebted to these two

gentlemen for the data they have provided, I also feel indebted to the many

dealers and collectors across the country and in Canada who keep me in mind when

they see one of these insulators. Without them, my collection would be rather

small, since there are very few of these insulators native to New England.

My

collection began in February 1974 with a single HEMINGRAY No 9. It was about

this time that I realized that I could never have all the different insulators I

saw. So when Dennis McHenry suggested the HEMINGRAY No 9 as a specialty, I took

the suggestion. Thanks to Dennis for steering me in this direction and for

providing pieces two through five, as well as others over the years. It took

only a short time for me to realize how much variation there was in these

insulators. So I devised a scheme of comparing certain features and using this

comparison as the basis for retaining or discarding an insulator.

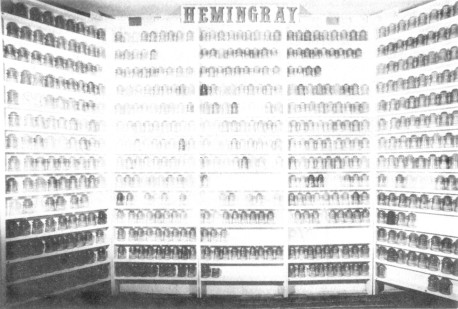

By 1976

and the 7th National in Berea, Ohio, my collection had grown to 210 pieces. At

this point I decided it was time to share the collection with the rest of the

collectors. I made a display of 192 pieces and took it to Berea. I was fortunate

enough to win the First N.I.A. trophy for the "Best Threaded Glass"

display. Just to display at a show with so many rare and exotic insulators was

an exciting experience. When my name was called as a winner, I was speechless. I

feel that my winning proved that a good display of inexpensive insulators has as

good a chance as any other display.

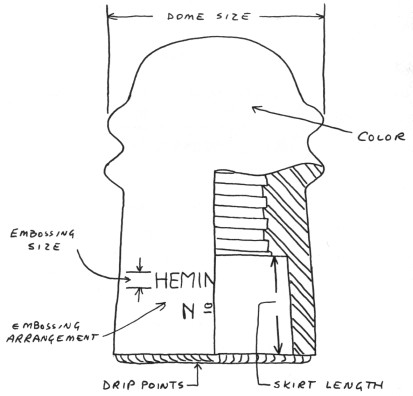

Figure 1. Features checked.

At the present time my collection contains

596 pieces, and my ground rules for selection are unchanged. Each new piece must

be different from all those already on the shelves. Figure 1 shows the features

I check to determine if I need the piece. In many cases over the years, I have

found little if any different extremes in the features I check. This is shown in

Table 1.

| Feature |

Beginning |

1976 National |

Today |

| Color |

1 |

23 |

28 |

| Dome size |

1 |

12 |

13 |

| Drips |

1 |

19 |

20 |

| Embossing arrangement |

1 |

9 |

10 |

| Embossing size |

1 |

5 |

5 |

| Skirt length |

1 |

24 |

24 |

Table 1.

Quantity of different features.

Several of

the features I check demand further explanation and clarification. The first of

these is color. Color seems to be the most difficult thing to standardize in our

hobby. So, whenever possible, I use the color stated by the person providing the

insulator. Sometimes I have made up my own colors, so as to have control over

the pieces in my collection. Anyone viewing the collection might disagree with

the way I have named the colors, and that is their right. For now, though,

through my eyes I see the colors as listed in Table 2.

1

|

Aqua

|

11

|

Gray

|

21

|

Green-McDougald

|

2

|

Aqua-dark

|

12

|

Green

|

22

|

Green-medium yellow

|

3

|

Aqua-green

|

13

|

Green-apple

|

23

|

Green-olive

|

4

|

Aqua-pale

|

14

|

Green-bright

|

24

|

Green-seven up

|

5

|

Blue

|

15

|

Green-dark

|

25

|

Green-yellow

|

6

|

Blue-bright

|

16

|

Green-Denver

|

26

|

Jade milk

|

7

|

Blue-ice

|

17

|

Green-emerald

|

27

|

S.C.A.

|

8

|

Blue-powder

|

18

|

Green-forest

|

28

|

Straw

|

9

|

Clear

|

19

|

Green-ice

|

|

|

10

|

Clear-near

|

20

|

Green-lime

|

|

|

Table 2. Colors.

In addition to

the 28 real colors listed in Table 2, I have one piece which has been irradiated

and has changed from Seven Up green to Amber.

Embossing arrangements are the

next thing I wish to explain. At this time I have what I consider to be ten

different embossing arrangements. These are listed in Table 3. The dates shown

in this Table were provided by Mr. Woodward from information he has on file.

From 1934 on, various mold set, mold and year numbers were also embossed on the

insulators. I have chosen to disregard these numbers to keep my records from

becoming too cumbersome.

| |

|

Year Mold Made |

Year Used |

1.

|

HEMINGRAY/No9//PATENT/May 2 1893

|

1895

|

1895-1900

|

2.

|

HEMINGRAY/No9//PATENTED/May 2 1893

|

1900

|

1900-1908

|

3.

|

HEMINGRAY/No

9//PATENT/May 2 1893

|

1900

|

1900-1908

|

4.

|

HEMINGRAY-9//MADE IN U.S.A.

|

1921

|

1921-1955

|

5.

|

HEMINGRAY/No9//PATENTED

|

1908

|

1908-1909

|

6.

|

HEMINGRAY-9/0//MADE in

U.S.A.

|

1933

|

1933

|

7.

|

HEMINGRAY//No9

|

-

|

-

|

8.

|

HEMINGRAY/MADE IN U.S.A.//No9

|

1919

|

1919-1920

|

9.

|

HEMINGRAY/No9

|

1910

|

1910-1918

|

10.

|

HEMINGRAY

|

-

|

-

|

Table 3. Embossing

arrangements.

The next feature to discuss is what I call manufacturing defects.

To spot these, each insulator must be examined very closely. Sometimes I have

missed a defect on my first examination, only to find it in later handling of

the insulator. Defects I have found include:

- Amber, black, jade or white

spots, swirls or streaks in the basic color of the insulator.

- Bubbles in

glass, sometimes many little ones, sometimes a few larger ones.

- Underpouring

of glass, resulting in incompletely formed drips or base of insulator.

- Ghost

embossing on various areas of the insulator, even inside the skirt.

- Skirt

shorter in some areas, as if it settled during cooling, causing insulator to

lean.

The final feature to discuss is what I call embossing errors. It

seems to me that most of these errors were caused by the mold makers not paying

close attention to their work. It also appears to me that there is no end to

these errors. Just when I think I have seen them all, a new one will show up.

Errors I have found include:

- Missing character(s), with or without space left

where character should have been.

- Double struck character(s).

- Backwards

character(s).

- Character(s) overstruck with other character(s).

Some classic

examples include:

- "HEMINGRAY/No" missing, front of insulator is blank.

-

Hemingray spelled "HEMINGAY".

- Hemingray spelled "HEMIGRAY".

-

Backward 9 in 1893.

- "PATENT/MAY 2 1893" overstruck with

"HEMINGRAY/No9".

My collection now includes three smooth base pieces.

These are usually the highest priced pieces I am offered, with SCA running a

close second. I still wonder if somewhere there isn't a smooth base with

"PATENT/MAY 2 1893" embossed on it. What a find that would be!!

And

that about concludes the updating of the HEMINGRAY No 9 story. I hope you have

enjoyed reading it as much as I have enjoyed telling it. I have had much

enjoyment in building up this collection and have made many friends in the

process. There are still plenty of inexpensive insulators around which could be

turned into great specialty collections.

If any of you happen to be passing near

my home, I invite you to see the collection. Only a few minutes notice is

required to get the museum ready for visitors.

|